When it comes to manufacturing, product data management, product development processes, and product lifecycle management (PLM), I’ve learned that problems are just part of the deal. It’s natural to want to fix everything right away, but let’s be real – trying to solve every problem at once is a recipe for getting stuck. I’ve seen it happen too many times. People spend forever planning for the perfect solution, and they never actually move forward.

The truth is, you don’t have to solve every problem right now. The idea that magic PLM software will solve all your problems is illusive. Some issues are going to stick around for a while, and that’s okay. Therefore, I prefer to speak about PLM solutions rather than PLM software systems. The key is figuring out how to live with those challenges while still making progress. I’m always taking each next step in the PLM implementation process from a project management perspective.

Here’s how I approach a successful PLM implementation…

Don’t Let Problems Stop You

When you’re implementing a PLM solution, you’re going to run into roadblocks – people resistance, data messes, inefficient processes, integration headaches – you name it. But here’s the thing: you don’t need to fix everything to make progress. Those are steps I suggest you do:

- Focus on Data

First things first, get your data in order. Figure out how you’re storing files, defining your product information, and tracking changes. A solid foundation here makes everything else easier. - Define the Core Process Loop

What’s the most important process for your team? For many manufacturers, it’s the handoff from engineering to manufacturing. Nail down the steps and make sure everyone’s on the same page. - Support Key Metrics (KPIs)

Decide what success looks like. Maybe it’s fewer late procurement orders or faster turnaround times. Whatever it is, make sure you’ve got a way to measure it. - Automate Where You Can

Automation is your friend. Look for repetitive tasks that take up time and see if you can streamline them.

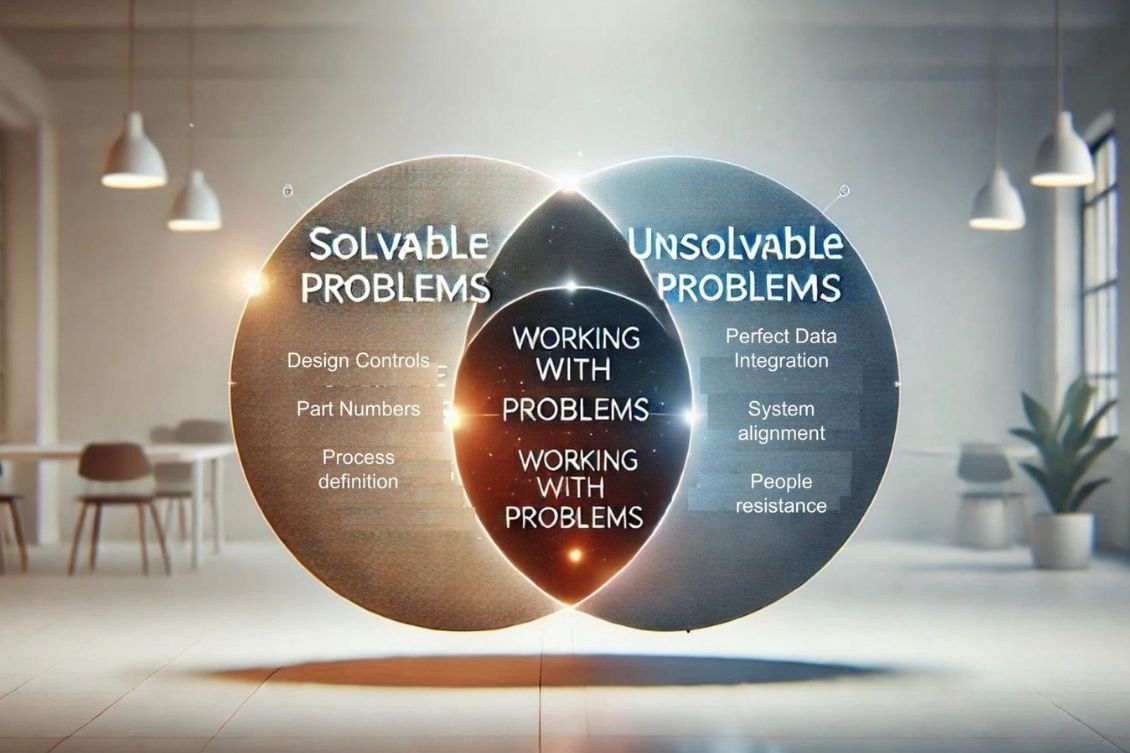

Solvable and Unsolvable Problems

In Product Lifecycle Management (PLM), certain challenges remain fundamentally unsolvable due to complex human and technological factors. Organizations continuously struggle with perfect data integration, seamless system alignment, and predicting market dynamics. These inherent complexities demonstrate that some problems cannot be definitively solved, but must be continuously managed and adapted to through strategic approaches.

Here is an example of solvable problems. Many challenges can be effectively solved through strategic technologies and approaches. Organizations can improve collaboration, streamline resource allocation, and enhance data management using integrated tools and centralized systems. By implementing comprehensive PLM solutions, companies can reduce product development time, integrate business systems, and accelerate market entry. Effective change management, design controls, and quality management enable organizations to optimize product development, ensure compliance, and drive operational excellence.

A Real-Life Example

Let me give you an example. One big challenge and very often a priority for many companies I’ve seen is the transition from engineering to manufacturing. Here’s how I’d tackle it:

- Get the Data in Shape

Make sure engineering data is clean and easy to share with manufacturing. Keep track of revisions and make the product definition crystal clear. - Automate Product Baselines

Set up automation to create baselines for engineering, manufacturing, and maintenance as part of the transition. It saves time and cuts down on errors. - Track Late Procurement Orders

Use a KPI like the number of late procurement orders to measure how well things are working. It’s a simple metric, but it tells you a lot.

Avoid Getting Stuck in Endless Planning

Having a big-picture vision is great, but you’ve got to take steps to get there. You need to focus on solvable problems – many problems can be solved by applying a modern PLM system approach, buying systems from the right PLM solution providers, improving product data quality, and focusing on the right PLM technology. You can improve team performance and automate tasks.

Here’s how I keep things moving:

- Set Small Goals: Break the work into chunks. Start with the most critical issues and build from there.

- Stay Flexible: Be ready to adjust as you go. You’ll learn things along the way that might change your approach.

- Work with your team: Make sure everyone knows the overall plan, but also emphasize that it’s about making steady progress, not perfection. Bring project managers who can balance tasks.

Conclusion and Final Thoughts

Business processes, complex product lifecycle, supply chain management – taking on these challenges as part of a PLM software implementation project can be overwhelming.

Look, no one can fix everything all at once, and that’s okay. By focusing on the basics—like data, processes, KPIs, and automation—you can keep moving forward. The goal isn’t to have a perfect system but to create one that gets better over time.

So don’t let the problems overwhelm you. Acknowledge them, find ways to work around them, and focus on making progress. You’ll be surprised how far you can go.

Interested to learn how OpenBOM can help?

REGISTER FOR FREE and check OpenBOM in real projects. We’re happy to help you with consulting and advice.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.