If you’re following our publications and recent release news in July 2024 you already know that OpenBOM introduced a groundbreaking service to manage multiple BOMs called xBOM. The idea behind this functionality is to support processes related to the management of multiple BOMs for different stages of the product life cycle – engineering (EBOM), manufacturing (MBOM), service and maintenance (SBOM), and many others.

Making things simple is one of the elements of the OpenBOM vision. We like to make PLM simple and therefore many decisions about user experience, functions, and processes are focusing on simplification. Each time we bring new services and functions, we like to innovate and make it simple.

The same is happening with xBOM. The world already has complex PLM systems to manage EBOM, MBOM, and other Bill of Materials. At OpenBOM, we want to make it simple.

If you missed some of our previous articles, please check these out:

- Introducing the OpenBOM xBOM service

- xBOM service: BOM management use cases

- OpenBOM xBOM architecture for the distributed digital thread

- OpenBOM architecture for xBOM and Role-based access control

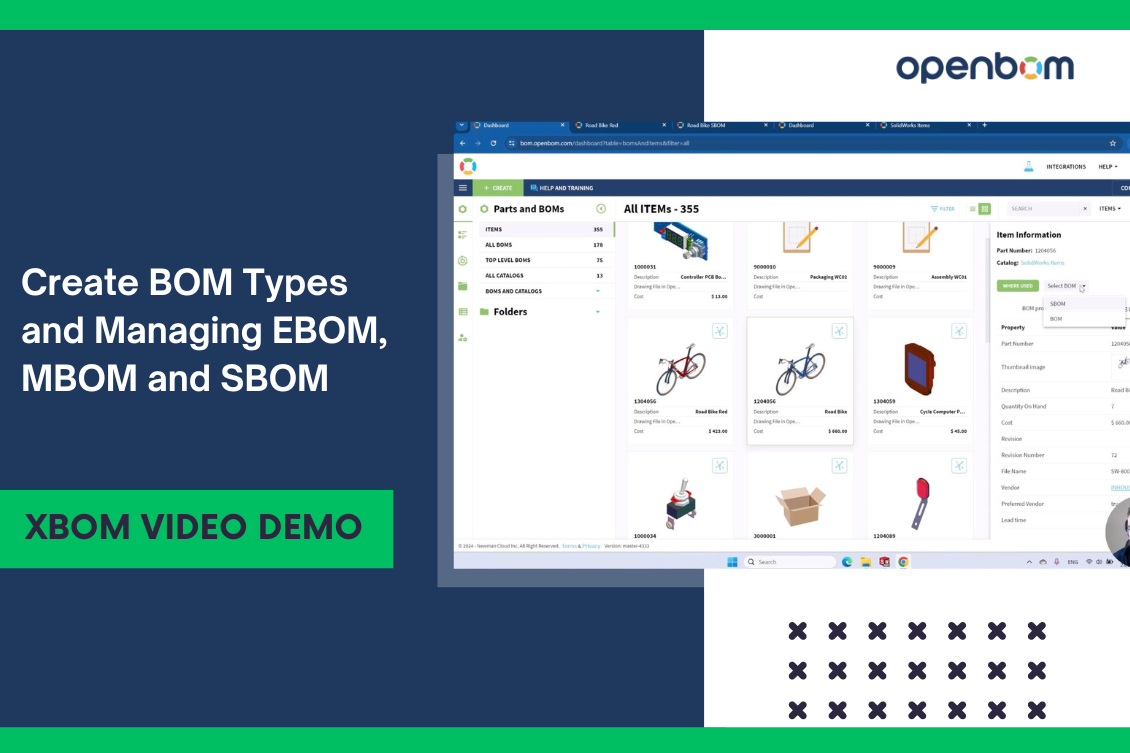

In my article today, I’d like to share a video demo of OpenBOM xBOM usage including the following 4 examples: (1) creating BOM types; (2) Navigating multiple BOMs; (3) Engineering, Manufacturing, and Service BOM examples. Also, you can see a video demo (the link is in the paragraph below)

BOM Types

This is basic administrative functionality for xBOM. It can be performed by the company admin and allows you to create whatever number of BOM types you need. However, we recommend some best practices and they include EBOM (engineering), MBOM (manufacturing), and SBOM (service and maintenance). You’re not limited to the number of BOM types and names.

Usually, BOM types reflect life cycle stages and separate work by multiple departments and teams.

BOM Types Navigations

OpenBOM remains friendly and simple until the admin adds more BOM types. Everything you did before will work the same and until you define more than one BOM type, all functions, menus, and commands will do the same thing as you regularly see.

Once you define more than one BOM type, things will change and BOM-related menus will get an additional context. You can see it in the picture below where you need to select the BOM types you need to open.

Best Practices: EBOM, MBOM, SBOM

How many BOM Types do you need? This is a great question. I will write a separate article about it, for simplicity, let me bring you the idea that every “lifecycle stage” or “process” will require an independent BOM type (here we come with Engineering, Manufacturing, and Service).

The EBOM (Engineering BOM) is a default BOM that is defined in OpenBOM. You don’t need to change anything. It is always defined and called “BOM”. All OpenBOM CAD integrations create this BOM and this is your starting point.

See in the picture below, how BOM (aka EBOM) is created using OpenBOM Add-in for Solidworks.

Once, the engineering BOM is created, we recommend producing a manufacturing BOM to allow you to perform production planning. It includes the segmentation of BOM for different workstations, and the creation of components to follow the assembly process. Check this one below – it is an example of MBOM.

Last, but not least in this list of BOMs is SBOM (maintenance and service). It gives you a separate representation of all items that need to be exposed to the sales and maintenance organization. In the picture below you can see an example of maintenance kit organization into a separate SBOM.

Watch the Video

Pictures are great, but a video is much better. In the following video, Pedro Branco demonstrates how OpenBOM allows you to administer and use different types of BOMs to organize product information. Watch this video.

Conclusion

OpenBOM brings a powerful set of functions to manage multiple BOMs (xBOM) to reflect the data and process structure for more advanced and complex organizations. Understanding multiple BOM management (EBOM, MBOM, SBOM, etc) requires a bit of planning upfront and we encourage you to check our documentation and work with our sales and customer success team to help manufacturers simplify the xBOM process.

If you like what you see, create an xBOM and start a trial to experiment with multiple BOM functions in real life.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.