We continue to discuss the capabilities of recently released xBOM services. It expands OpenBOM product structure (BOM) management in many ways by providing more robust and flexible data management capabilities to suit the customer needs. The idea behind this functionality is to create a digital thread of information using OpenBOM product knowledge graph model to support processes related to the management of multiple BOMs for different stages of the product life cycle – engineering (EBOM), manufacturing (MBOM), service and maintenance (SBOM), and many others.

Simplification is another key element of OpenBOM strategy. We take things that are traditionally designed to be complex (eg. BOM and PLM) and make things simple by changing the paradigm it works. Check the earlier articles we publish about xBOM.

- Introducing the OpenBOM xBOM service

- xBOM service: BOM management use cases

- OpenBOM xBOM architecture for the distributed digital thread

- OpenBOM architecture for xBOM and Role-based access control

- xBOM Video Demo: Create BOM Types and Managing EBOM, MBOM and SBOM

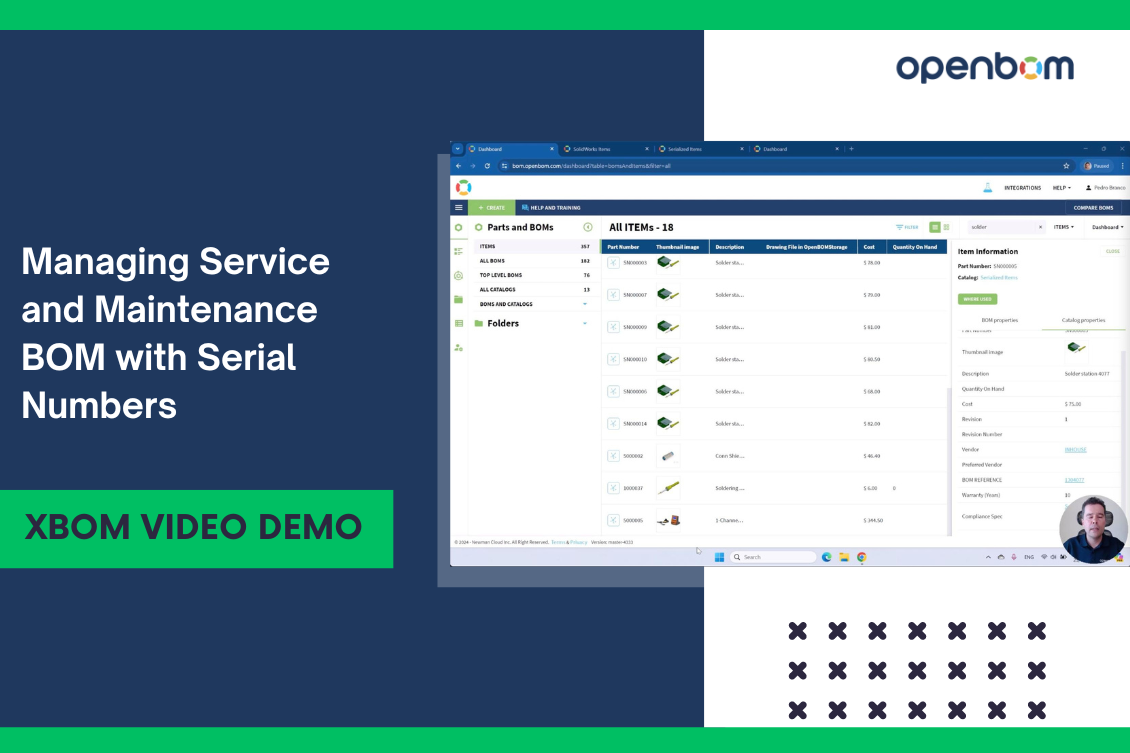

In today’s article, I want to share more information about how you can use xBOM for situations when you need to control the maintenance process and manage BOMs with Serial Numbers (serial BOM).

xBOM and Serial BOM architecture

OpenBOM multi-view BOM architecture allows you to create and maintain virtual representations of product structure for different BOMs. In our example for the purpose of maintenance, we demonstrate how you can manage EBOM (BOM created from CAD system with engineering modifications), then create an anchor SBOM for maintenance to include all S/N instances and then later connect specific SBOMs for each S/N as a copy of EBOM.

Demo Scenario – from EBOM to SBOM with S/Ns

Let’s see a step-by-step explanation of how you can make these moves. Everything starts with the engineering BOM (known as a “BOM” in OpenBOM). You create this BOM from the CAD system and later can modify it. Here is an example of EBOM.

Once you get an EBOM, you can switch to SBOM and add all serial numbers (S/N) of devices or products you manage to that SBOM. Each S/N is generated in a separately created catalog with a unique S/N generation pattern.

Generated S/N later added to the SBOM where they represent the list of all S/Ns. You create each SBOM for a specific S/N by cloning an engineering BOM (EBOM) and modifying the Part Number with S/N.

Video Demo

In the following video, you can see a demo of this EBOM to SBOM creation with guidance and instructions.

Conclusion

We are thrilled by the wide range of capabilities xBOM service brings to OpenBOM customers. The new xBOM capabilities help to reflect the data and capabilities needed for modern companies switching to service business models and managing complex and connected products. This is a place where new xBOM features shine.

Understanding multiple BOM management (EBOM, MBOM, SBOM, etc) requires a bit of planning upfront and we encourage you to check our documentation and work with our sales and customer success team to help manufacturers simplify the xBOM process.

REGISTER FOR FREE and check how OpenBOM xBOM service can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.