What is BOM management?

BOM management is important as it allows manufacturing companies to efficiently plan for the purchase of materials, estimate the costs of materials, manage their inventory, and sustain precise records.

A bill of materials (BOM), or product structure, is a comprehensive set of information that describes all items, quantities and related piece of data such as attributes, attachments, linked data describing what is needed of each to get a finished product.

BOMs combined with specification documents, drawings, and attributes represent the product digitally. BOMs specify the materials, dimensions, weight and quantities required to build a product.

Why do you need PLM and bill of materials (BOM) management?

BOM management enables you to share the latest product designs and BOMs with your teams.

BOM information is usually spread across different siloed systems and spreadsheets. CAD systems are typically use to manage the mechanical, electrical, electronic/PCB and software designs. But these systems are mostly used by engineers, but teams accross the lifecycle have limited access and visibility to the product data stored in these systems.

With a single source of product truth, you’ll gain the control and transparency you need to act and bring your products to the next level. Your teams will be have access to key product information and you’ll have centralized control of the entire product records in different product lifecycle stage, which will create a complete digital thread of product information.

Your engineering teams will be able to pass the product designs from CAD to a centralized location where everyone can easily access and consult key information.

Why is OpenBOM different?

The core of OpenBOM is a global, multi-tenant, flexible information model. It provides an easy way to organize product data records (extract, integrate, and manage revisions, changes, history, and other information including file, references, images, and other data types).

With OpenBOM, you can easily integrate with your favorite CAD software to import and export your items and BOMs, and bring all of your information together into a single platform.

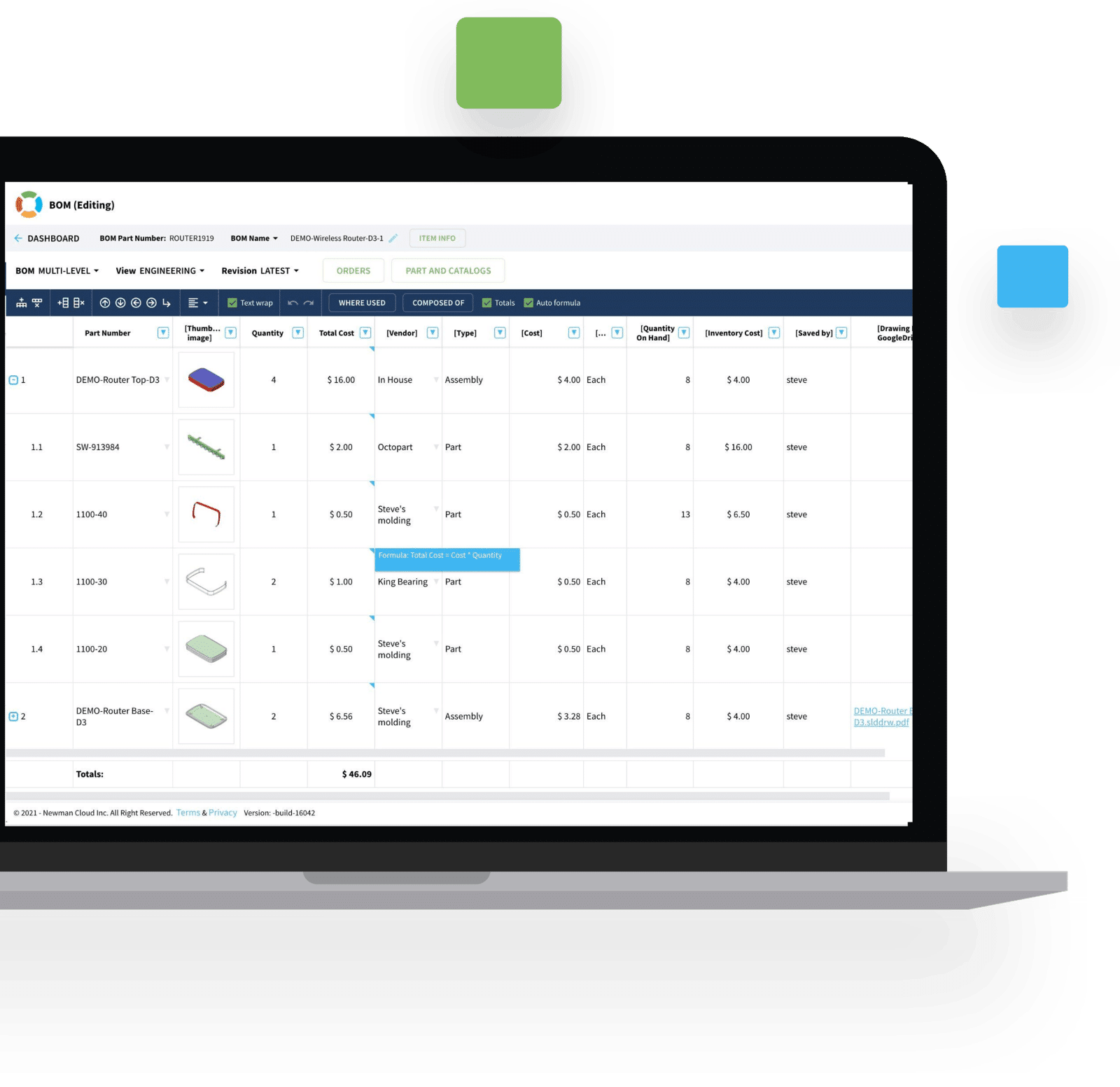

OpenBOM is easy to navigate with its friendly (and highly customizable) “Excel-like” look and feel user interface. As it is cloud-based software, you can easily share data and collaborate online with suppliers and contractors.

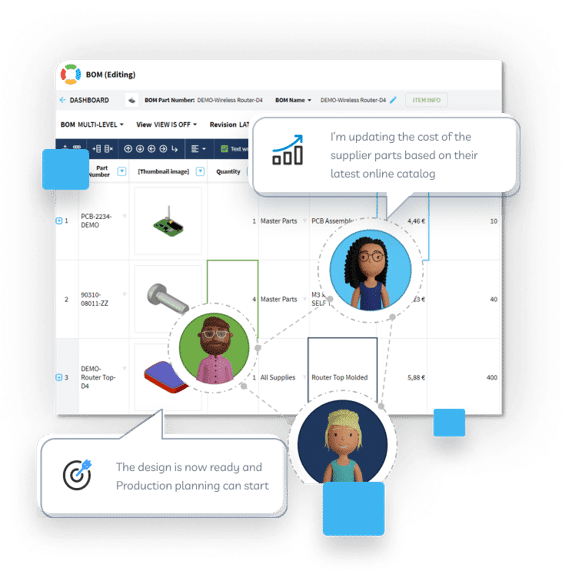

Whether your teams are collocated, distributed, or fully remote, OpenBOM provides an engaging, intuitive, instant collaboratiur on experience with multiple options for real-time or asynchronous teamwork on an online product structure.

Your teams will be able to enrich and consolidate product information. And once product the information is consolidated in a central location, you’ll be able to share your BOMs along with key product information with your suppliers and downstream processes.

OpenBOM’s patented simultaneous data sharing and editing capabilities allow you to collaborate within the team and across multiple companies.

Efficient BOM management allows you to have an accurate overview of products/projects. This means you will be less likely to run out of materials as all teams are working together with the same information.

How does OpenBOM work?

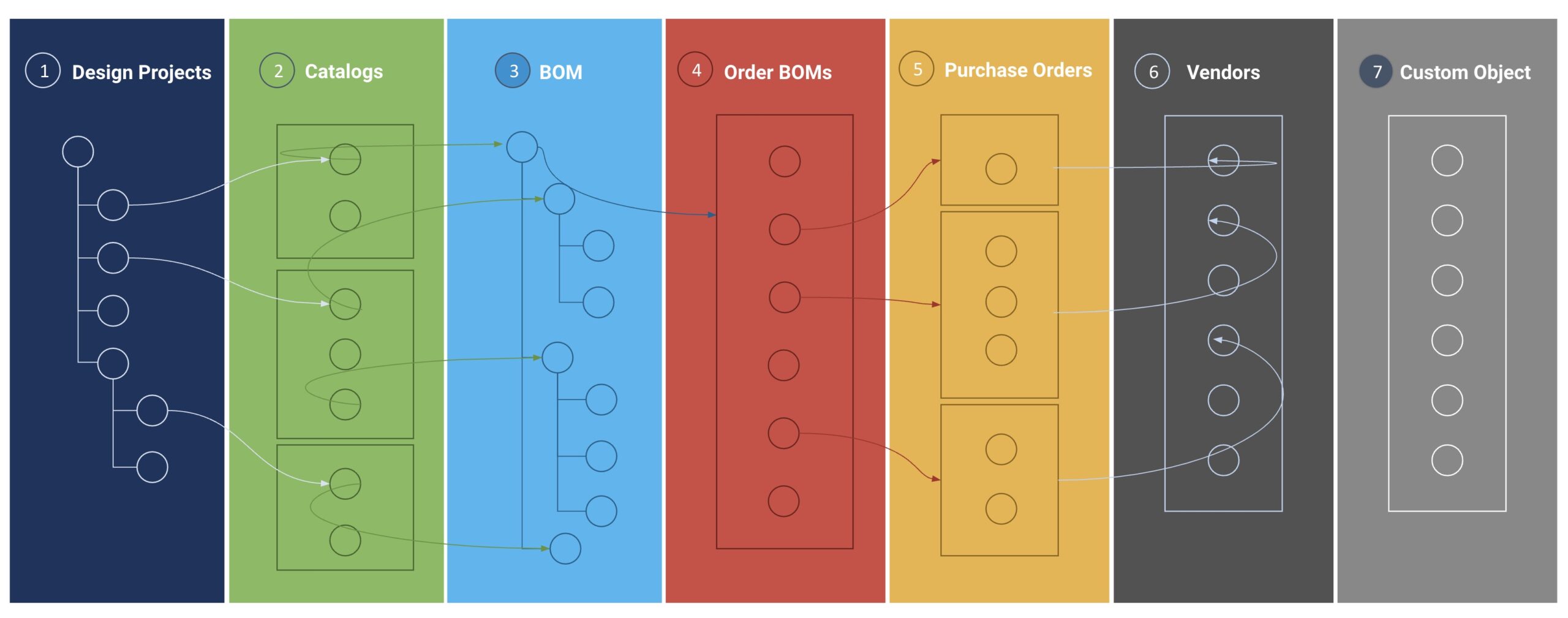

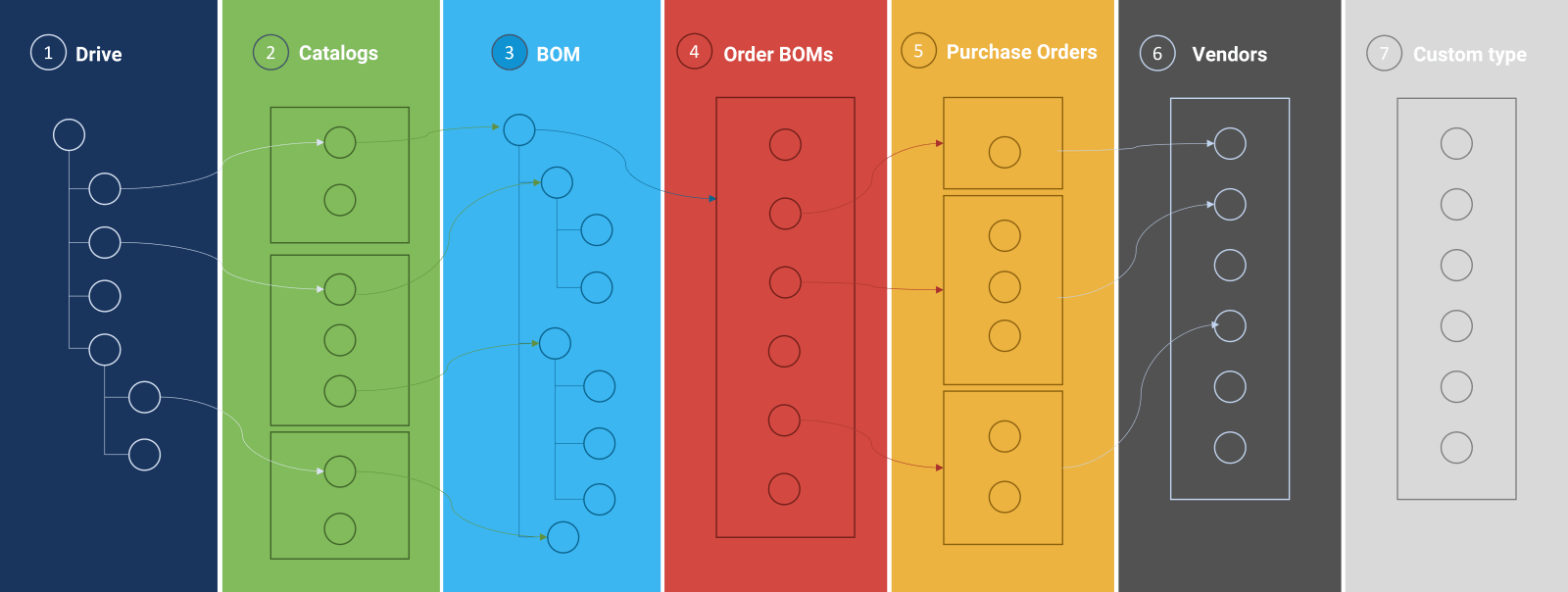

The data management architecture of OpenBOM is built using flexible data objects holding different information sets semantically connected together. These data objects are flexible and generic allowing you to build any data structures using predefined and fully customizable attributes. The multi-tenant data model allows role-based access to data shared between multiple companies.

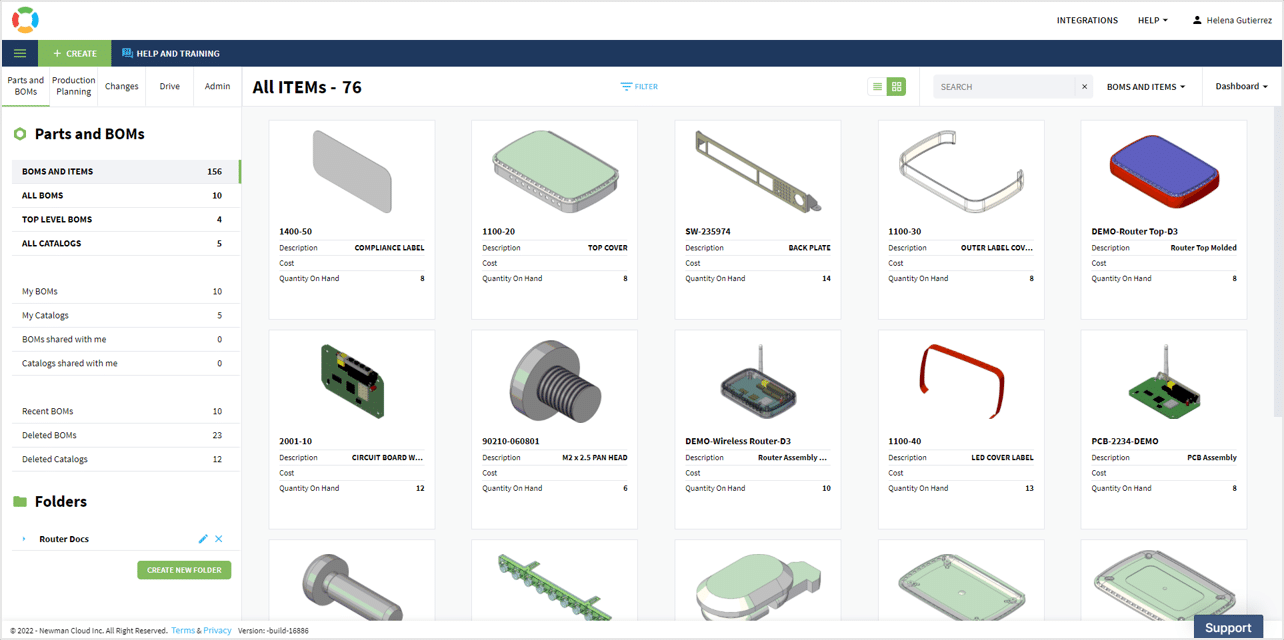

With OpenBOM, you can easily create individual items using catalog functions and then use them to create a bill of materials.

With OpenBOM, you can easily create individual items using catalog functions and then use them to create a bill of materials.

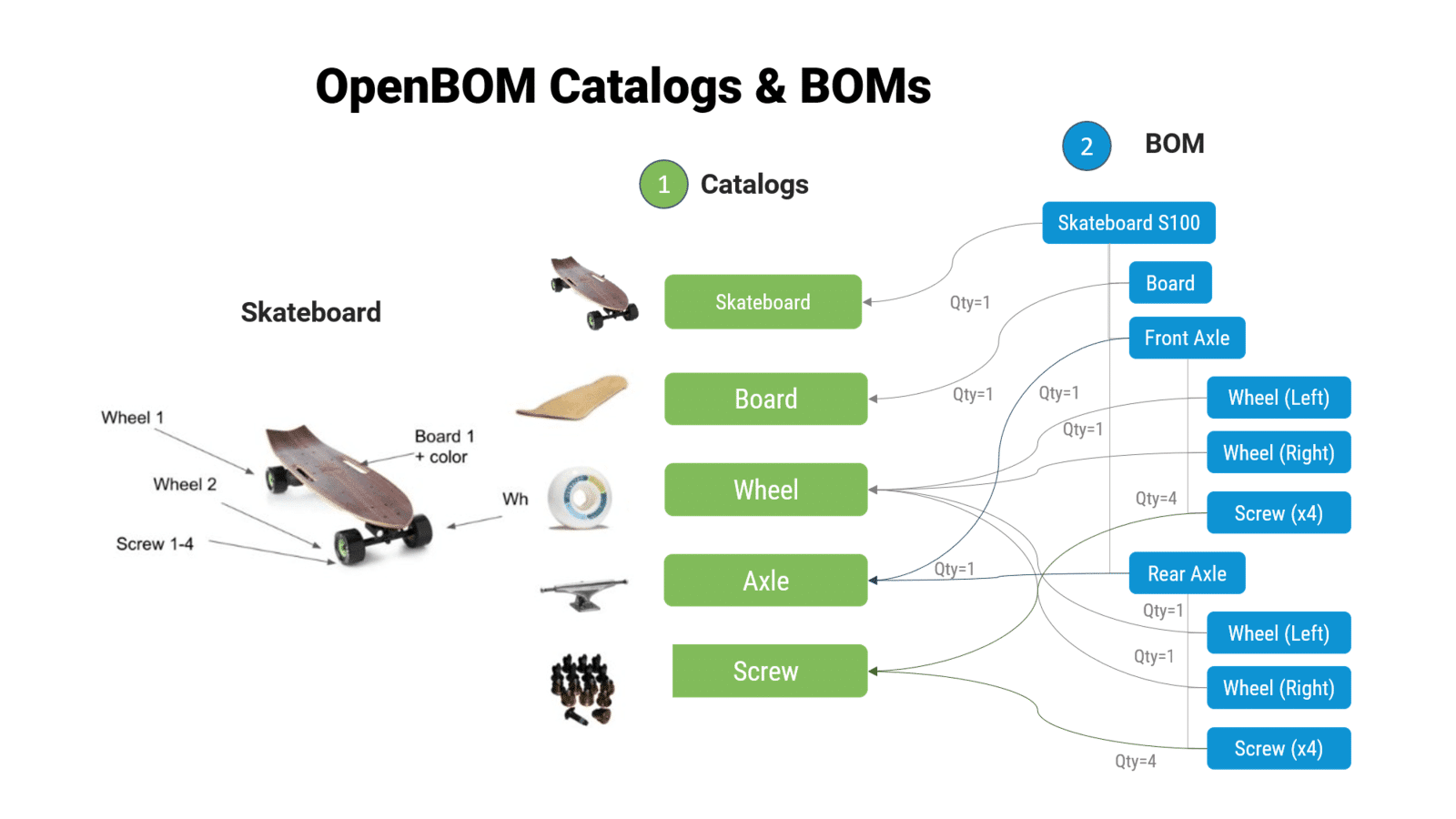

Catalogs and BOMs are the key elements of OpenBOM’s information model. Let’s look at an example to walk through these concepts.

In this example, the BOM of the skateboard is built using catalogs as a basis.

Catalogs are used to organize your standard items, engineering items, and products, and are reusable. You can think of your catalogs as a database for all items you can use in your BOMs

Once you have created a BOM, you can easily insert individual items by entering a part number directly into the list. This will add the item and all of its related information that was entered when the item was created, meaning you do not need to manually import any data.

Although OpenBOM has a simplistic look and feel that can be compared to Excel, BOM management is extremely flexible and you are easily able to navigate between single level, multi level, and flattened BOM views. These view changes can easily be accessed from the drop-down list within a BOM.