A quality management systems (QMS) is a set of policies, processes, and procedures required for planning and execution (production/development/service) in the core business area of an organization (i.e., areas that can impact the organization’s ability to meet customer requirements). Check more about QMS systems here.

The challenge to get safe products to market

Manufacturing companies these days are under pressure to deliver products on time and with the desired quality. The quality of the management system is critical for their success. The compliance requirements are very strictly enforced and requirements are diversified based on the country, industry, and type of products.

Without the proper organization of product data, it is very difficult to control everything that goes into your product. Multiple Bill of Materials controlling different parts and systems are used by different members of the team making it impossible to validate and release information together with the product.

Benefits of using OpenBOM

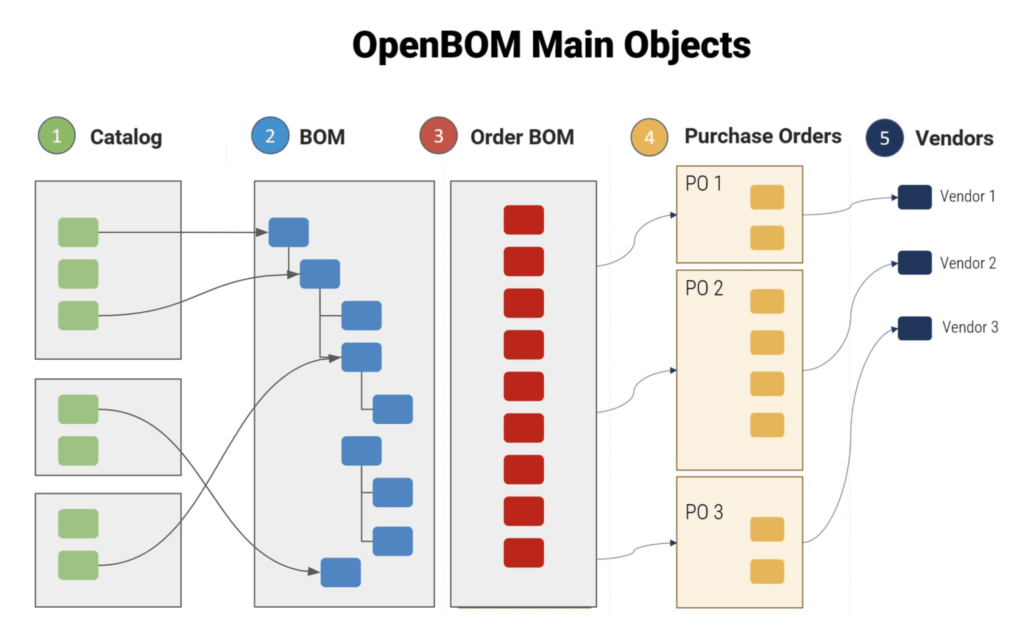

There are many types of quality management systems and processes. When it comes to the question of selecting the software for quality management systems, companies are usually asking a set of multi-disciplinary questions. One of the most important is integration with product information and bill of materials. To have it integrated with product management and BOM tools is critical. OpenBOM flexible data model allows us to create a full set of quality records. Combined with the OpenBOM instance reference model, which allows creating a single version of truth for items, instances, and all related product lifecycle information, OpenBOM PLM provides full access to information needed for the organization of the quality control process.

Why OpenBOM is better?

OpenBOM is an online service available on-demand via the browser. It combines a unique set of features to manage product structure and connect all related pieces together. A unique flexible data model and real-time collaboration allows customizing the data schema on the fly and creating a source of all quality data connected to product records. It makes OpenBOM implementation very simple and easy.

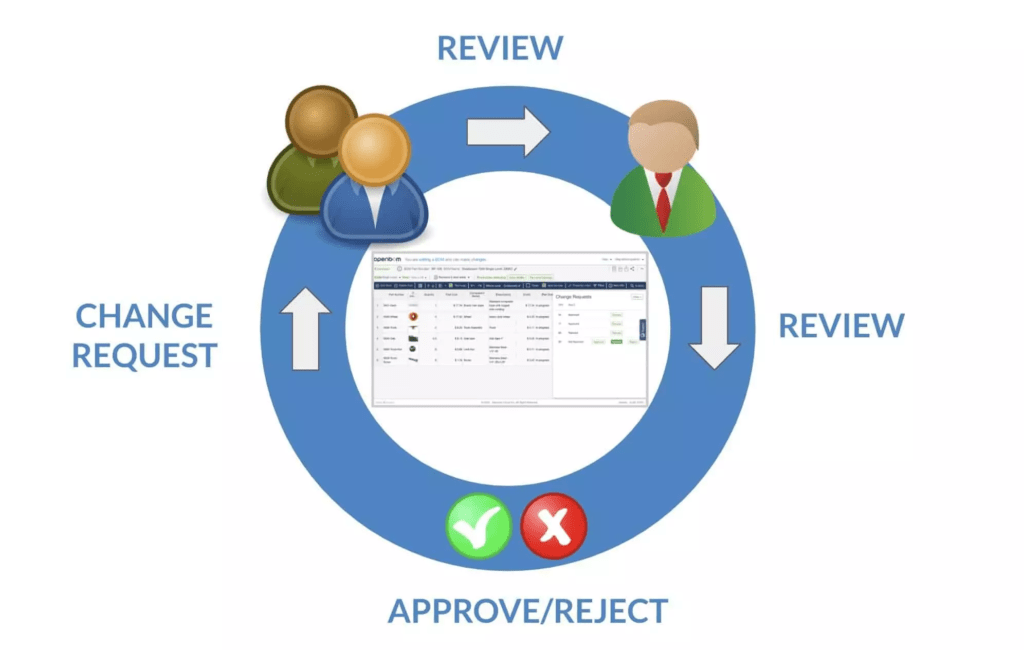

OpenBOM automatically tracks history and allows us to organize an immutable electronic record of changes for traceability of who made any change and the reasons or the change. Combined with fully immersive engineering integrations, OpenBOM allows you to support traceability between BOM records and related engineering documents.

OpenBOM is integrated with many enterprises and engineering data systems allowing you to build a multi-disciplinary data repository to track all your product information and provides QMS features to your team.

Here is a summary of OpenBOM differentiators:

1- SaaS, instant registration. Available in minutes, no need to install/

2- Ease of user (Google Spreadsheet like user experience)

3- Track history changes and revisions automatically.

4- Integrated with all CAD, PDM, and PLM tools.

5- Provides real-time collaboration and simultaneous editing of BOMs and related data.

6- Share data in real-time with everyone via email.

Read more about OpenBOM data objects

Read more about how OpenBOM supports revisions and change control