FENCEQUIP had always prided itself on innovation. As a New Zealand-based manufacturer of post drivers, they were known for their ability to create high-quality, durable equipment. But behind the scenes, they faced a challenge that many manufacturers encounter—the disconnect between engineering and procurement.

For years, their engineers worked diligently in Autodesk Fusion 360, designing cutting-edge products. But getting those designs translated into accurate purchasing decisions was another story. Manual processes bogged down the flow of information, leading to inefficiencies, unexpected costs, and inventory headaches. The team knew that to truly optimize their manufacturing process, they needed to bridge the gap between design and procurement.

The Breaking Point: When Old Methods No Longer Work

The problem became more apparent as FENCEQUIP grew. Engineering and purchasing operated in silos, with valuable design data stuck inside CAD models while procurement teams scrambled to interpret spreadsheets and emails to determine what to order. Sometimes, mistakes were caught too late—materials were either over-ordered, increasing waste and tying up capital, or under-ordered, causing production delays.

Costs were another challenge. Without real-time visibility into material expenses, engineers had little insight into the financial impact of their designs. By the time purchasing reviewed the orders, it was often too late to make cost-saving adjustments. The inefficiencies were adding up, and FENCEQUIP knew it was time for a change.

Finding the Right Solution: OpenBOM’s Seamless Integration

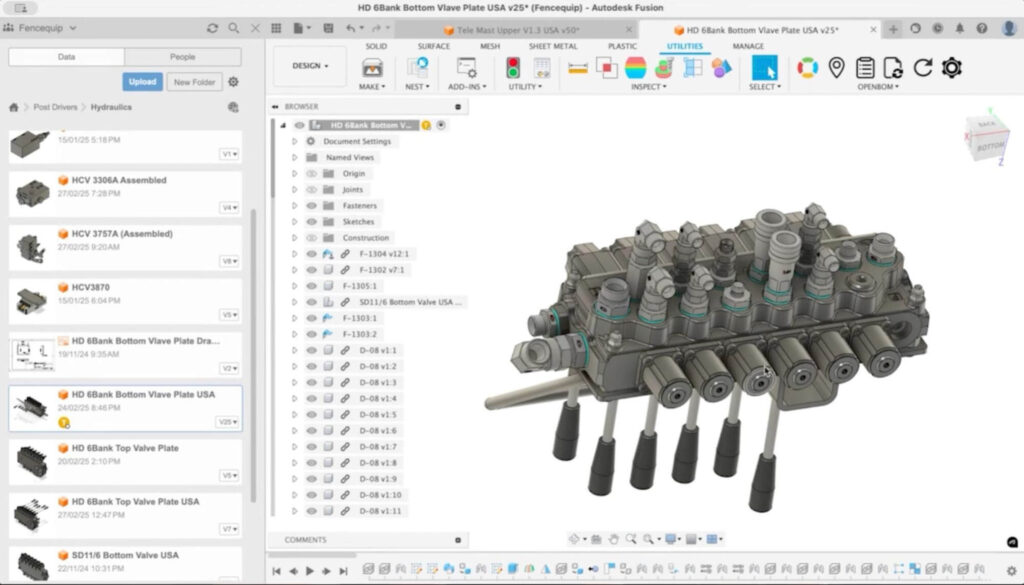

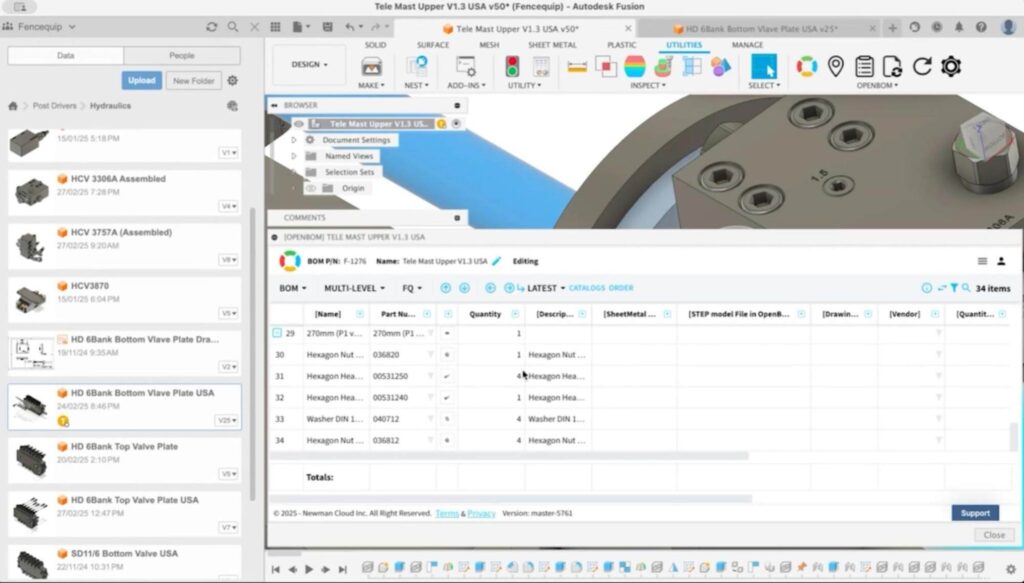

Determined to modernize their process, FENCEQUIP turned to OpenBOM. The cloud-based platform promised a direct integration with Autodesk Fusion 360—exactly what they needed to create a seamless connection between engineering and procurement. The idea was simple: eliminate the manual steps and let the data flow effortlessly from design to purchasing.

As soon as they implemented OpenBOM, the difference was night and day. Engineers could now generate accurate Bills of Materials (BOMs) with just a few clicks, and those BOMs were instantly accessible to procurement. No more outdated spreadsheets. No more back-and-forth emails trying to clarify what needed to be ordered. Instead, the entire team operated from a single, always-updated source of truth.

Smarter Purchasing and Leaner Manufacturing

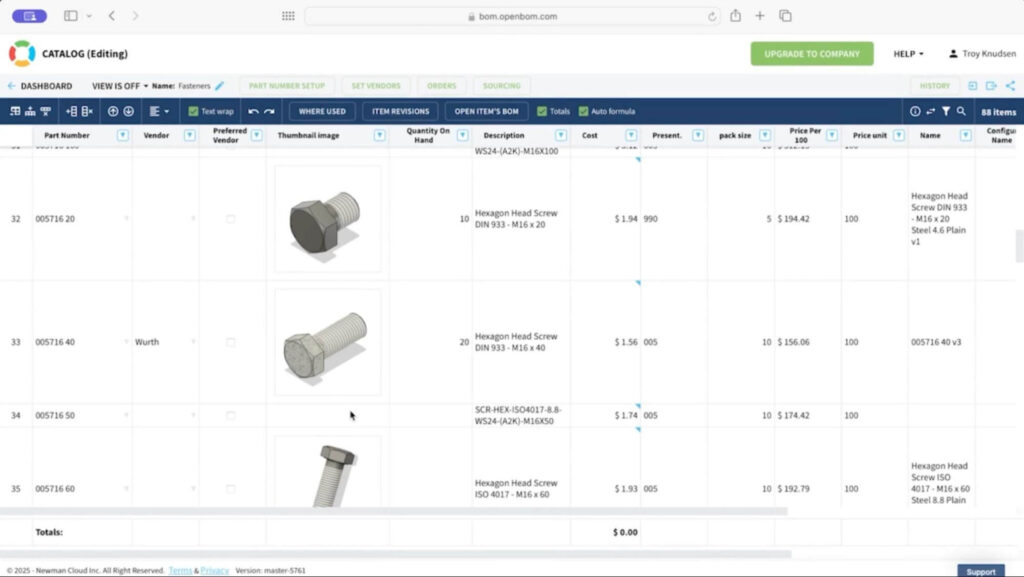

With OpenBOM in place, FENCEQUIP quickly saw improvements beyond just better communication. Cost analysis became part of the design process rather than an afterthought. Engineers now had real-time visibility into material costs and supplier options, allowing them to make cost-effective decisions before production even began. This shift helped reduce unnecessary expenses and ensured that every purchase was made with efficiency in mind.

Another game-changer was inventory management. Before OpenBOM, the company frequently struggled with over-ordering or misaligned supplier purchases. Now, procurement teams could see exactly what was needed, when it was needed, and from which supplier. This precision reduced waste, optimized order quantities, and helped FENCEQUIP negotiate better deals with suppliers. The result? A leaner, more cost-efficient operation.

The Human Factor: A Team That Makes a Difference

Of course, technology alone doesn’t drive transformation—people do. One of the unexpected benefits of adopting OpenBOM was the partnership that came with it. The OpenBOM team wasn’t just there to provide software; they became a crucial part of FENCEQUIP’s journey. From answering questions to helping tailor the system to FENCEQUIP’s specific needs, their support made the transition smooth and effective.

“The OpenBOM team was responsive, knowledgeable, and genuinely invested in our success,” said a FENCEQUIP representative. “Having that level of support made all the difference in making the change stick.”

See the Transformation in Action

To see how FENCEQUIP has successfully implemented OpenBOM, check out this video where we walk through their seamless Autodesk Fusion integration, cost-saving strategies, and purchasing optimizations.

A Smarter Future for Manufacturing

What started as a frustrating challenge has now become a competitive advantage. FENCEQUIP has transformed its operations from a fragmented, inefficient system into a connected, cost-optimized, and agile manufacturing process. By integrating engineering, procurement, and cost management, they have not only saved time and money but have also gained the flexibility to scale their business with confidence.

For any manufacturer looking to improve their design-to-purchase workflow, OpenBOM offers a proven solution. Whether dealing with complex product structures or seeking better control over inventory, OpenBOM delivers the tools and expertise to make it happen.

For more information about FENCEQUIP check this website https://www.fencequip.net.nz/

For more information about OpenBOM, check here – https://openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.