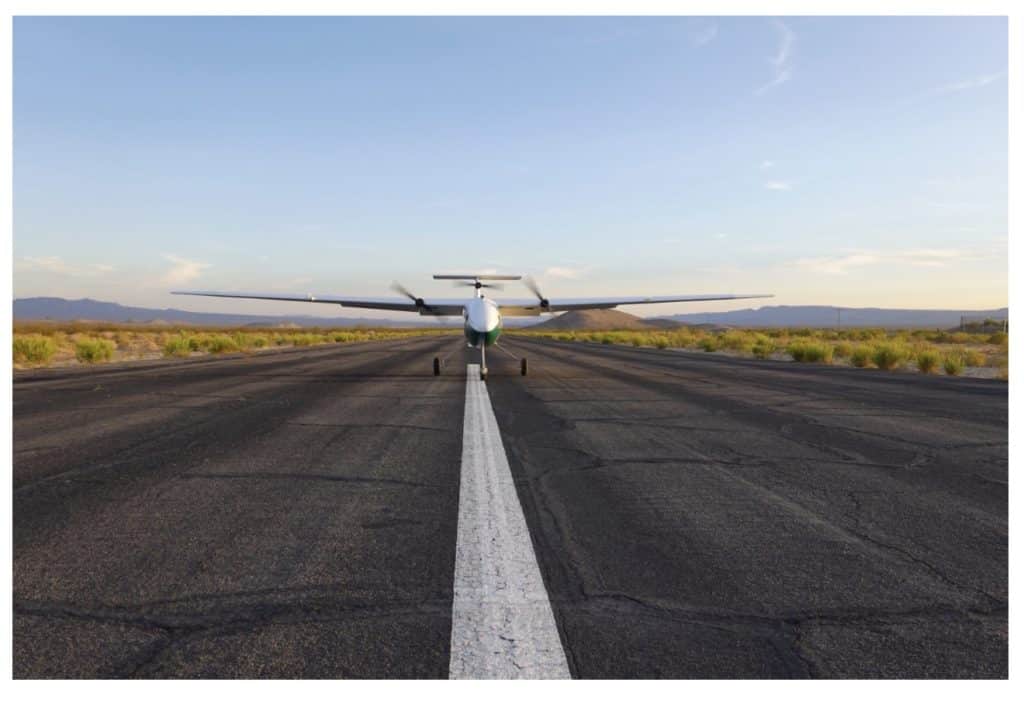

Pyka is a leader in autonomous electric airplanes. Their autonomous crop duster is a thing of beauty on the outside and a sophisticated engineering accomplishment on the inside and all of us at OpenBOM are proud to be helping Pyka meet its commitments and delivery goals!

Founded in 2017 by experienced aviation experts, Pyka brings the reliability and high performance of short take-off and landing (STOL) airplanes to the agriculture industry in the form of an autonomous “crop dusting” airplane.

As Pyka transitioned from concept to design they needed a way to manage their prototype phase all the while with an eye towards production. When they brought in OpenBOM for Teams to manage the product builds they were laying the groundwork for manufacturing.

This is no model airplane by any means…… The Pelican model has a 38’ foot wingspan,

100 gal spray tank and is fully autonomous. Once programmed with a mission, it will complete a flight task while compensating for wind, drift, and all the other things which make crop-dusting more of an art than a science.

Pyka Lead Mechanical Engineer Garrett Rini described the product’s evolution “moving from prototyping to production manufacturing is really hard. We needed to button down parts, assemblies, and procedures and pass that information along to the manufacturing teams.”

“Our airplanes have lots of parts and assemblies to keep track of across two distinct teams, Engineering and Manufacturing, and we need to be on the same BOM all of the time. Getting all of that info straight was a big problem and Google sheets wasn’t going to get us there.” Says Garrett.

“We were basically trying to build OpenBOM in Google sheets,” he says.

After a bit of research, OpenBOM for Teams was a perfect fit for this rapidly growing company.

“One thing that was attractive was the low barrier to taking us several steps further than Google sheets. We could import directly from Solidworks, an existing Google sheet, or just type in data. OpenBOM functions the way we would expect it too.” says Garrett.

Pyka relies on OpenBOM for Solidworks integration to reliably capture product structure and design intent. That means a reliable way to create BOMs of designs that contain the expected items AND a reliable way to update them as they evolve.

While the primary design tool is Solidworks, Pyka has a bit of everything including PCBA and other tools. Two teams and eight engineers all creating data and BOM changes to eventually make a product.

“At this point, we are tracking OTS (off the shelf) parts, in-house designs, assemblies, sub-systems, PCBAs, and more. Give it a part number, put it in a BOM. Boom, done.”

The Pyka team also often has to answer that classic question, “Which motor controller is in what plane?” Well, the OpenBOM Where-Used feature helps them do just that.

They also like the way non-modeled parts can easily be added to the BOM in OpenBOM, no longer requiring the CAD engineer to account for every screw or fastener.

“When we share the BOM with the manufacturing team, they simply click the link, get the proper step file or control specification. No copies of documents or files, no more emailing or validating if we have the proper STEP file”.

Finally, Garrett says “OpenBOM is the Pyka source of truth! It’s a huge benefit for everyone involved. We put everything in there and we can pull back out just the views and information that is relevant to each party involved. We simply couldn’t do that with a spreadsheet”.

To learn more about Pyka visit www.flypyka.com

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.