Gaius Automotive is on track to solve that most difficult problem of all in package delivery… the last mile. Their patented tilting three wheeled electric vehicle will hit the market in 4Q 2021 with a blend of maneuverability, capacity and efficiency.

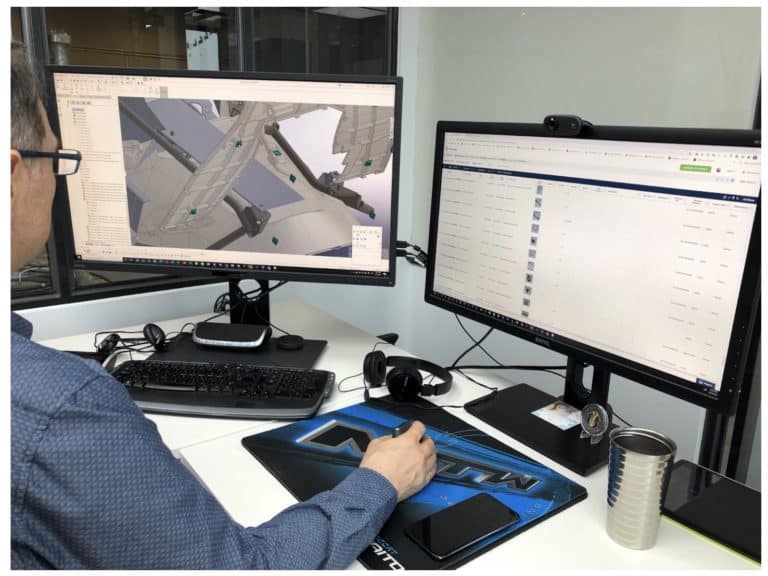

The company’s CTO, a former US race team engineer, brings a blend of performance and technology and an innovative approach which required a new way of thinking about design, parts and supply chain, and OpenBOM was just the partner to provide it.

Specifically, how to ensure that everyone on the team, from designers in Canada, to partners in Taiwan and around the world, are all looking at the exact same set of data; always.

Managing Engineer Ray Chen says “the OpenBOM Access by View and Share by View functions are a powerful feature. It allows us to maintain one set of master data then strictly control who has access to it.”

In the simplest form, Gaius Automotive uses the OpenBOM Company and Team administration to control who can edit and who can view the Bill of Materials.

But it goes much deeper.

“Each department has its own View of the data, literally”, says Chen. “Department heads can see a broader scope of the design BOM and properties, while individual team members may get views of the data specifically tailored for them.”

Gaius creates a master set of Items (parts and assemblies) in an OpenBOM Catalog, which is a single, cloud-based, instance of all their parts, assemblies, and related metadata (properties).

The Gaius Engineers and planners create BOMs in OpenBOM which are shared with the team using specific methods and Views; OpenBOM automatically applies the rules described above so each team member gets that personal view. OpenBOM also controls who and what can or cannot be seen by others on the team.

“For example”, says Chen, “Our design verification BOM may be different then the next evolution of the design coming along, we use OpenBOM to manage that design maturity and who sees the BOM at which phase of the design process.”

“We like how we can create an M-BOM structure that correlates with our processes,” says Chen.

Gaius benefits from OpenBOMs ability to keep track of parts, part numbers, and descriptions in a way which Excel just can’t. Excel does not give them control over Part numbers or the ability to check for duplicates. They like the ability to ask OpenBOM for the next part number in a series.

“Organizationally, Excel cannot do Flatten BOM. Flatten BOM is crucial to our production processes so we can determine exact quantities. In our process, we use the OpenBOM multi-level features to create an MBOM, then, we create a mid-level assy and organize items under it. We like how we can restructure the BOM. OpenBOM works for manufacturing much better than excel.”

According to Ray Chen, Gaius really likes the day-to-day productivity gain which comes with the browser-based application. “I keep three tabs open all the time….. 1) Catalog, 2) BOM 3) OpenBOM Dashboard and just quickly switch between them.”

To learn more about Gaius Automotive please visit http://www.gaiusauto.com/

To learn more about OpenBOM visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.