Displace TV is redefining how televisions are mounted, offering a completely wireless, vacuum-powered solution that eliminates the need for brackets, drilling, or complex installations. But behind this sleek, futuristic product was a major challenge: managing an increasingly complex design and manufacturing process.

Don’t trip over a pebble on your way to the mountain. This simple saying gives us a powerful reminder: even the boldest visions can be derailed by small, avoidable obstacles.

Manufacturing companies are climbing mountains to invent amazing products and breakthrough technologies. But many stumble—not because of the challenge itself, but because they rely on outdated file-sharing methods, manage procurement in clunky spreadsheets, or miss critical deadlines like showing up too late at CES. In this race against time, speed and precision are everything.

When traditional file management systems started slowing them down, Displace TV turned to OpenBOM. The results? A streamlined workflow, improved collaboration, and a faster path to market.

The Challenge: Managing Complexity in a Fast-Paced Environment

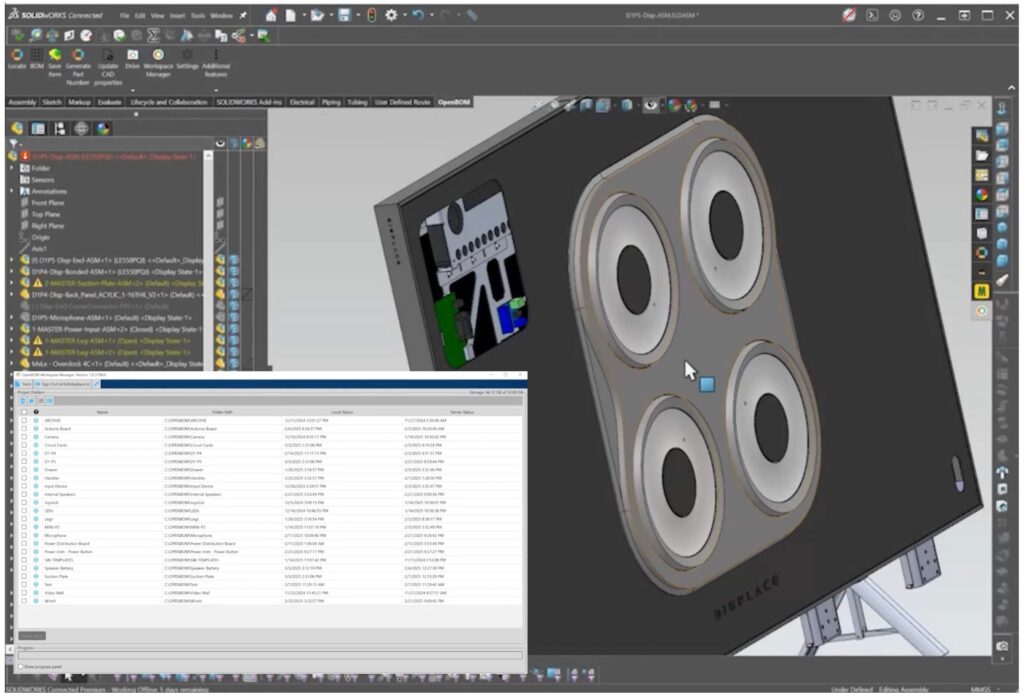

Developing a first-of-its-kind product like Displace TV requires more than just an innovative idea—it demands seamless coordination across engineering, design, and manufacturing teams. As their product took shape, the team encountered several roadblocks. Version control became a recurring issue, with engineers frequently facing file overwrites and outdated BOMs in SOLIDWORKS. Product data was scattered across multiple systems, making it difficult to track key details like components, materials, and suppliers. Collaboration was another challenge, as team members working in different locations struggled to stay aligned on design updates.

Scaling production introduced yet another layer of complexity. As Displace TV prepared for manufacturing, they needed a more structured approach to managing parts, suppliers, and costs. Initially, they relied on Google Drive to share design files, but as the project grew, this method became unmanageable. They needed a better way to organize, track, and synchronize their product data—without slowing down innovation.

The Solution: OpenBOM’s Seamless Integration with SOLIDWORKS

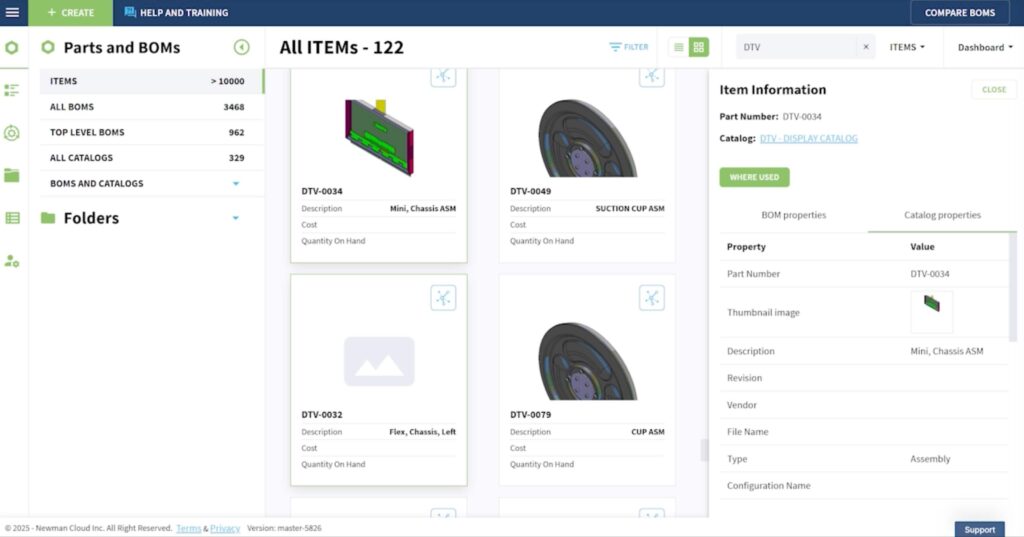

To solve these challenges, Displace TV turned to OpenBOM, and the transformation was immediate. By integrating OpenBOM with SOLIDWORKS, engineers could automatically extract metadata, BOMs, and part structures directly from their designs, eliminating the need for manual spreadsheet updates. The cloud-based platform also enabled real-time collaboration, ensuring that every team member had access to the latest product data, preventing version conflicts and miscommunication.

With OpenBOM’s structured BOM and part management system, Displace TV replaced scattered files and email threads with a centralized hub for tracking components, materials, and suppliers. This streamlined production planning, making the entire process far more efficient. Engineers also gained instant access to critical design data, eliminating the frustration of searching through folders for the latest specifications. With OpenBOM, everything they needed was just a click away.

The Impact: A Smarter, Faster Path to Production

With OpenBOM in place, Displace TV dramatically improved its product development process. Engineers spent less time managing files and more time innovating. Collaboration between teams became effortless. And when it came time to move from design to manufacturing, they had full visibility into every part, cost, and supplier.

Displace TV’s journey proves that even the most groundbreaking products need the right digital tools to succeed. By replacing outdated file-sharing methods with OpenBOM’s structured approach, they’ve eliminated chaos and accelerated their path to market.

Watch the Full Story

Want to see how Displace TV transformed their workflow? Check out this video interview where they share their experience with OpenBOM.

Efficiency Drives Success

Every delay in product development translates into lost opportunities. With OpenBOM, Displace TV streamlined their workflow, reduced inefficiencies, and gained full confidence in their data. Their story is proof that the right digital tools don’t just save time—they drive real business success.

For more information about Displace TV – https://displace.tv

For more information about OpenBOM – http://openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.