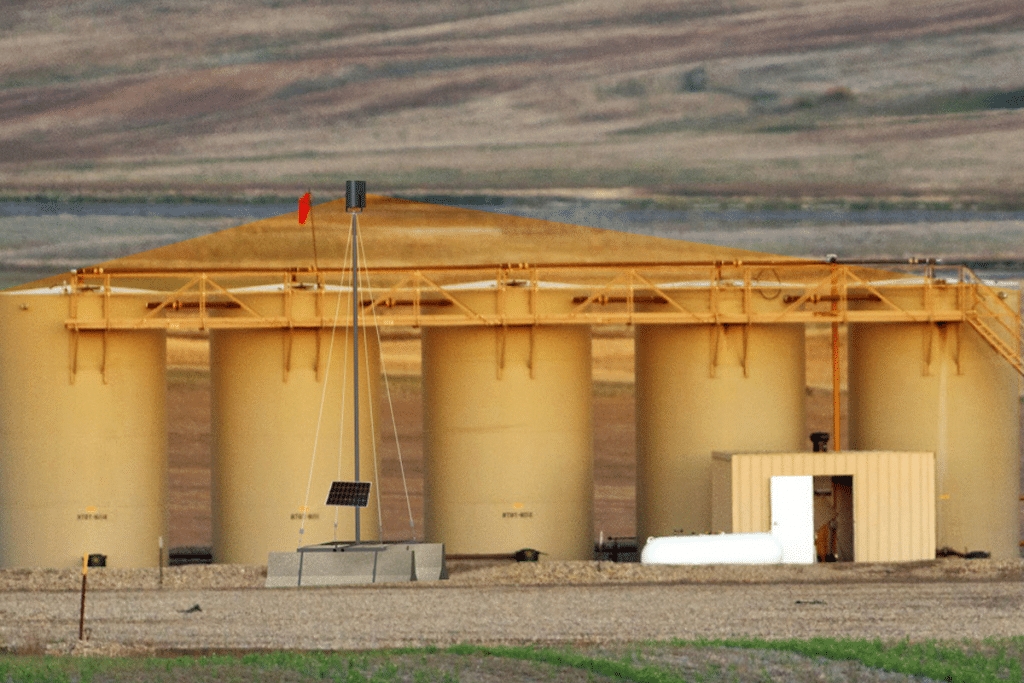

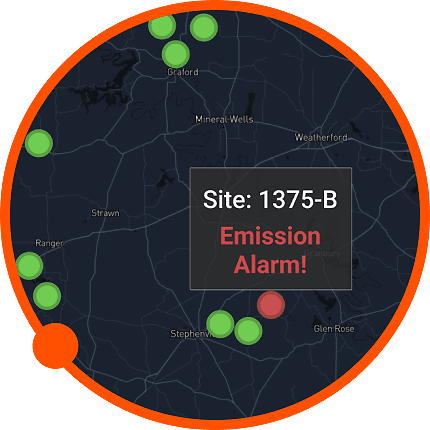

Cambridge, Massachusetts-based Kuva Systems literally keeps an eye out for methane gas leaks. Using novel spectral imaging systems, combined with powerful real-time algorithms, Kuva’s GCI360 Camera provides continuous monitoring of upstream and midstream oil and gas sites. By automatically alerting operators on the ground when a leak occurs, Kuva enables their partners to improve safety, and prevent a potent greenhouse gas from polluting the atmosphere.

Founded in 2015 by Jason Bylsma, the company has been developing sophisticated imaging technologies and is quickly ramping up as sales grow in the oil and gas industry and many others.

Kuva System’s Mechanical Engineer Ethan Skutt and I have been working together quite a bit lately as the company scales and now relies on OpenBOM to forecast component demand and costs and manage inventory.

“OpenBOM quickly produced an accurate and complete Bill of Materials from our CAD models”, says Ethan, “something we had been struggling with our non-integrated Google sheets based process.”

Kuva strives to deliver the best value in the continuous methane detection space and has recently increased demands on both internal and external planning and manufacturing.

“As we moved into manufacturing, we just didn’t have an accurate BOM with reliable pricing, vendors, and lead times,” says Ethan, “we didn’t know how much our product cost.”

According to Ethan, “we started with a complete BOM in OpenBOM, then looked towards costing, forecasting and manufacturing planning.”

“The OpenBOM staff coached us on how to set up our inventory management system,” he explains, “helping us decide which CAD properties were important, how to bring them to OpenBOM, and how to extend the item property definition in OpenBOM.”

“We quickly had a reliable way to go from CAD model to a multi-level BOM in OpenBOM.”

Over time, Kuva established OpenBOM as their inventory management system, extending the item master definition and associating important planning and manufacturing information about each item.

“Once we had a BOM and items, OpenBOM helped us to quickly move on to more advanced aspects of inventory management like automatic part numbering, item demand forecasting, and quantity-on-hand management.”

“As we matured as a company, OpenBOM became the catalyst and enabling technology for many of our internal business processes.”

Ethan and his team rely on OpenBOM to calculate the exact quantities for all items in the BOM using OpenBOM’s unique ability to roll-up costs and other properties through multiple levels of the BOM.

“The Quantity Gap feature of the Planning (Order) BOM is exceptional,” he says. “We no longer have production interruptions due to on-hand shortages.”

“I literally run the gap calculations 10 minutes before the company planning meeting and have up-to-the-minute numbers for order demand, items shortage risks, and visibility into longer planning activities.”

“Something we didn’t see coming with OpenBOM is the benefit to others in the company who consume engineering and BOM information. We have non-technical people using OpenBOM to better understand where a particular item is used, how many of an item exists in a sub-level BOM, or any other item usage information, all without taking time from the Engineer.”

“OpenBOM is used by the entire team at Kuva Systems and saves us many hours every week in BOM and inventory management. We understand costs and gaps and our inventory in nearly real-time.”

“Simply put, we have a better BOM.”

To learn more about Kuva Systems please visit.

Learn more about Kuva and its founders.

To learn more about OpenBOM please visit the website.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.