Brian Kraut and EA Manufacturing of Florida, USA, rely on OpenBOM and Autodesk Fusion 360 to solve a major manufacturing issue for a leading provider of massive outdoor structures. OpenBOM and Autodesk Fusion 360 collaborate to solve leading outdoor structure designers’ major problems!

By Brian’s admission, he uses OpenBOM in an “unusual” way which I will tell you about now. Oh, I need to be intentionally vague on the details as there are real IP issues here. So please forgive my dancing around some of the details.

Brian was contacted by a new client in big trouble. They had a very large investment of time and money into a design (by another design firm) which was ready to go to manufacturing. But the client could not go to the manufacturing phase because they didn’t know how many of each component they needed. The client asked the original designer to provide the detailed Bill of Materials but they could not. Keep in mind this is a complex design, with mirrored parts, left and right parts, assembly variants, configured lengths, etc.

“My client was stuck and needed someone to take their design data and turn it into a manufacturing Bill of Materials”, says Brian. This is where EA Manufacturing and OpenBOM stepped in.

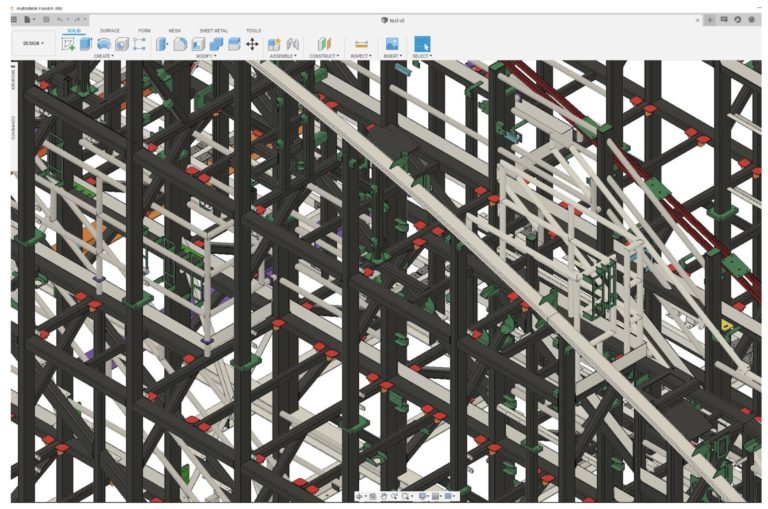

The client sent Brian a STEP file over 1.2Gb! Brian uploaded the file(s) into Autodesk Fusion 360 and began to organize the design. He discovered the design had over 24K individual parts, which OpenBOM and Autodesk Fusion 360 handled nicely.

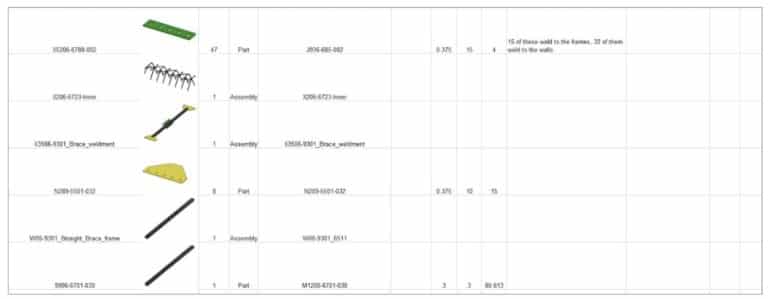

Brian used the OpenBOM for Autodesk Fusion 360 add-in to create a Multi-Level BOM of the entire design. However, it was OpenBOMs Flatten function which really provided the power Brian (and the client) needed. Brian used Flatten to identify ALL the individual parts and assemblies AND THEIR QUANTITIES (regardless of their location in the product structure) so they could take the design of the steel manufacturer and have the correct number of parts made!

Flattening the BOM to calculate the exact quantities could not be done without OpenBOM!

While Fusion 360 was capable of creating a parts list on the drawing, Brian needed to visualize the entire product structure as one BOM, that’s where OpenBOM really delivered for him.

“I love how the thumbnail images displayed on the screen and in the exports. The material types, thicknesses and other part properties also came through into the BOM literally saving me hours of time specifying material properties for each part” says Brian. “Having Multi-Level product structure is great!” he added.

Brian’s client was so happy they also purchased an OpenBOM subscription and loved the collaboration aspect eliminating the need to send BOM data back and forth through emails. Brian says “My client loved having one single source of truth for their BOM mastered in OpenBOM.”

Brian continues to use OpenBOM with each of his clients.

To learn more about EA Manufacturing go to www.eamanufacturing.com

To learn more about OpenBOM go to www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.