When the University of Wisconsin-Stout Industrial Design (ID4) class of 2020 needed to “think” about how their capstone project would be manufactured, class lecturer and professor Kerstin Nye went looking for some way to introduce her students to “real” manufacturing & planning…. She chose OpenBOM.

“These are Industrial Design students with an early understanding of the design process. UW Stout’s iD program looks to enhance how we teach with real-world experiences such as having students create a Bill of Materials for their product designs” Kerstin explains.

As I was once a young Mechanical Engineer, I recall the experience.

Kerstin challenged her ID4 class to conceptualize an electric lamp; then design (many used CAD of some sort), consider the impacts and alternatives, evolve, and finally select an alternative which they would take beyond the concept by creating and presenting a manufacturing and marketing plan. This would be their preferred design.

OpenBOM would play an important role in each design as students, many for the first time, selected specific manufacturing information about the bits-and-pieces of their design.

In May 2020, the class presented their Lamp design in an online (it was Covid-19 time you may recall) Zoom meeting and final design review which I was honored to attend.

Each student individually presented and defended their design and decisions and received a critical review. Ultimately each presented a glossy marketing slideshow and final Bill of Materials (OpenBOM) of their design.

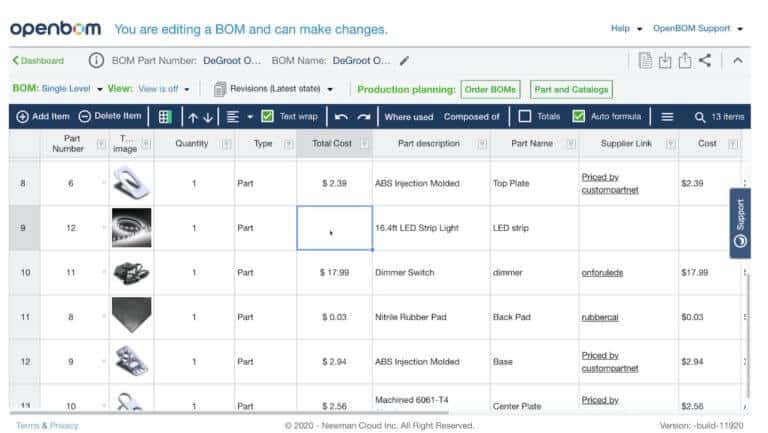

Student Jacob DeGroot used Solidworks for his design; “The Solidworks/OpenBOM works seamlessly. I never knew it was possible to build and update a BOM so easily from Solidworks” he said. “Near the end of the project, I was constantly making revisions and clicking Update BOM to send last-minute changes to OpenBOM”.

According to Kerstin, “The onboarding process for the students could not have been easier, I simply treated the class as an OpenBOM Team with me as an administrator, I added each student’s email to the team and they had immediate access to all OpenBOM features.”

“All the tooth grinding and stress of Excel was just gone!” she says.

Students used OpenBOM from the very start to visualize the parts list and add non-CAD properties like Cost, Vendor, and lead-times.

“During the first few days I relied heavily on the Skateboard sample data available in the OpenBOM Dashboard from the start” Jacob went on to say. “It gave a general idea of process and formats, literally what a proper BOM looked like, customary column order and property names, and much more – as a student, I never would have known that.”

Many students found the answers to their questions in the OpenBOM Online Help and Youtube channel. “I started with How to import an Excel Spreadsheet to see what my old BOMs looked like in OpenBOM and just kept going from there,” says Jacob.

While all the students really managed their OpenBOM experience entirely on their own I must say the personal experience of attending the student’s final design presentations was exceptional.

I hope to be invited back again!

To learn more about University of Wisconsin-Stout Industrial Design visit https://www.uwstout.edu/programs/bfa-industrial-design

To learn more about OpenBOM please visit www.openbom.com.

Steve Hess

OpenBOM, Director of User Experience

To learn more about OpenBOM visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.